MGE

Engineering Excellence

The Perfect Partner for your Press

Dampening and Circulation Units

0.5kW - 20.0kW

Dampening & Circulation Systems

MGE have been producing dampening and circulation equipment for the Print Industry for 50 years. The PressMate range of circulation systems are the latest generation offering a selection of units, from a basic circulation tank with no cooling, through to our 20kW pumpback system capable of servicing a large Multi-Tower Web Press installation.

Designed in conjunction with our customers, PressMate units offer printers new levels of performance ensuring high quality print output while the modular design allows easy access for routine maintenance and servicing.

PRESSMATE CS105 and CS210 (0.5kW \ 1.0 kW)

Our smaller CS105 and CS210 Pressmate systems are water dampening circulators for use in offset lithographic processes. Designed for use on one and two colour sheet fed presses, they provide refrigeration, circulation to \ from the press, filtration and alcohol dosing. A redesigned cabinet provides easy access with a fully removeable front panel makes the unit significantly more service friendly. And with MGE's proven alcohol control system and anti-foam filtration bags, the result

is a simpler, better solution to support all your printing needs.

The CS105 and CS210 incorporate:

-

0.5kW or 1.0kW of refrigeration using a simplified in-tank cooling coil

-

15 or 25 litre working capacity solution tank

-

One \ Two press feed(s) and Venturi suction return(s)

-

A choice of two alcohol systems for conventional printing

-

A no alcohol option for alcohol free printing

To complement the Pressmate dampening units, MGE offer Fount Dosing solutions, used to control the pH level of the fountain solution. The Auxiliary Tank and MX-1 dosers are available

for the CS105 and CS210 if fount dosing is required.

PRESSMATE CS420 and CS440 (2.0kW \ 4.0 kW)

Our CS420 and CS440 Pressmate systems are designed for use on slightly larger mid size sheet fed presses, they provide refrigeration, circulation to \ from the press, filtration and alcohol dosing. The redesigned cabinet provides easy access with detachable panels making the unit significantly more routine maintenance and service friendly. And with MGE's proven alcohol control system and anti-foam filtration bags, the result is a simpler, better solution to support

all your printing needs.

Our CS420 and CS440 units incorporate:

-

2.0kW or 4.0kW of refrigeration using a plate heat exchanger

-

95 litre working capacity solution tank

-

4, 5 or 6 press feeds and returns

-

Digital temperature display

-

Autofilling for the water tank

-

In-line filter protection for the suction venturi

-

Alcosystem or alcomixer alcohol control for conventional printing

-

No alcohol option for alcohol free printing

To complement the Pressmate dampening units, MGE offer Fount Dosing solutions, used to control the pH level of the fountain solution. The MX-2, MX-3 and MX-4 dosers are available for these size systems if fount dosing is required.

PRESSMATE CS660, CS680, CS6100 (6.0kW \ 8.0kW \ 10.0kW)

Our larger CS660, CS680 and CS6100 PressMate systems are designed for use on larger sheet and web fed presses, they provide refrigeration, circulation to \ from the press, filtration and alcohol dosing. The redesigned cabinet provides easy access with detachable panels making the unit significantly more service friendly and with MGE's proven alcohol control system and anti-foam filtration bags, the result is a simpler, better solution to support all your printing needs.

Our CS660, CS680 and CS6100 units incorporate:

-

6kW, 8kW or 10kW of refrigeration using a plate heat exchanger

-

170 litre working capacity solution tank

-

Multiple press venturi feeds and returns or pumpback tank option

-

Digital temperature display

-

In-line filter protection for the suction venturi

-

Alcosystem or alcomixer alcohol control for conventional printing

-

No alcohol option for alcohol free printing

-

Attachments for optional dosing equipment

To complement the Pressmate dampening units, MGE offer Fount Dosing solutions, used to control the pH level of the fountain solution. The MX-2, MX-3 and MX-4 dosers are available for these size systems if fount dosing is required.

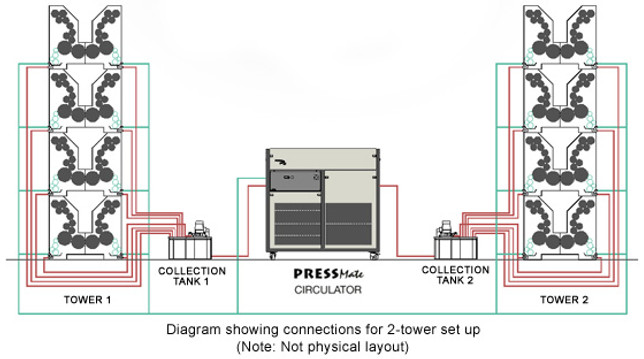

For larger presses, a pumpback system can be used instead of the venturi suction returns. Pump back systems come with either 60 or 120 litre collection tanks and are fitted with a filtration tray as standard. An optional second pump can also be installed to provide immediate backup in case of an issue with the primary pump.

PRESSMATE CS1150, CS1200 (15.0kW \ 20.0kW)

Our largest units are MGE's CS1150 and CS1200 Pressmate systems designed for use on wide format sheet and large web fed presses. They provide refrigeration, circulation to \ from the press, filtration and alcohol dosing. The redesigned cabinet provides easy access with detachable panels making the unit significantly more service friendly. And with MGE's proven alcohol control system and anti-foam filtration bags, the result is a simpler, better solution to support all your printing needs.

Our CS1150 and CS1200 units incorporate:

-

15.0kW or 20.0kW of refrigeration using a plate heat exchanger

-

250 litre working capacity solution tank

-

Options for multiple press feeds and returns to match requirements

-

Digital temperature display

-

Option to add MGE Alcosystem for alcohol control

-

Autofilling for the water tank

-

Options to add pH and conductivity monitoring and display

-

Attachments for additional dosing and filtration equipment

To complement the Pressmate dampening units, MGE offer Fount Dosing solutions, used to control the pH level of the fountain solution. The MX-2, MX-3 and MX-4 dosers are available for these size systems if fount dosing is required.

For larger presses, a pumpback system can be used instead of the venturi suction returns. Pump back systems come with either 60 or 120 litre collection tanks and are fitted with a filtration tray as standard. An optional second pump can also be installed to provide immediate backup in case of an issue with the primary pump.